We guarantee your satisfaction with our work

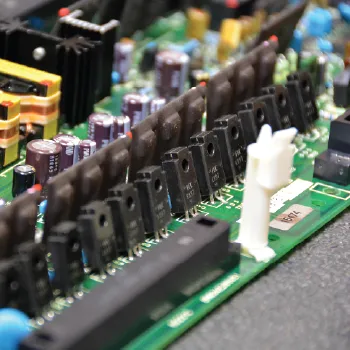

AC & DC Drives repair has been our core focus since the day our business was founded in 2004. We started with Yaskawa and Magnetek AC/DC drives and have grown our OEM brands to include others like Fanuc, Mitsubishi, Okuma, and many more.

We have over 50 years of combined experience working on industrial electronic repairs and can solve any problems you have with your drives.

Satisfaction Guarantee

Specialized Focus

Expanding Expertise

Extensive Experience

Problem-Solving Skills

Wide OEM Brand Support

(847) 465-9060

(847) 465-9060  Back

Back