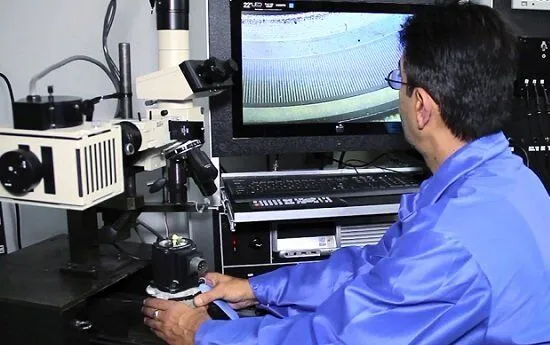

We make sure to have the latest and greatest test equipment to get your encoder or feedback repaired and tested as quickly as possible. These devices can be very complicated to repair both electrically and mechanically. Many have proprietary communication protocols that require special testing equipment.

Precision Zone has test equipment for Yaskawa, Mitsubishi, Siemens, Okuma, Heidenhain, Fanuc, lndramat, Sick, Sick-Stegmann, Tamagawa, BEi, Sumtak, Dynapar, and many more!

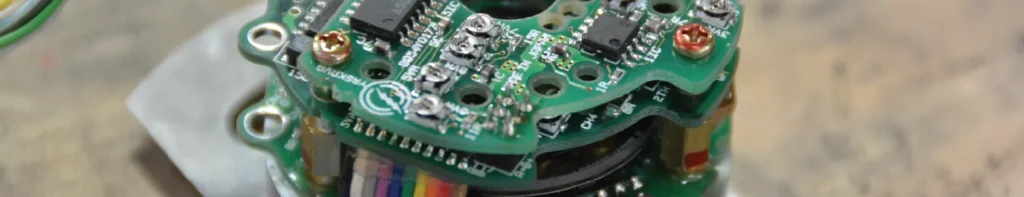

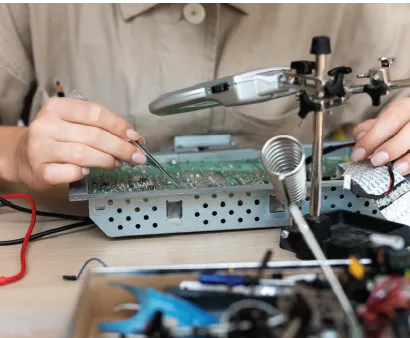

Bad pickup, scratched glass, damaged electronics, bent shaft, bad bearing, output pulses missing and a few of the common issues that our techs can easily repair. Send your feedback device or motor in for a free evaluation today!

(847) 465-9060

(847) 465-9060