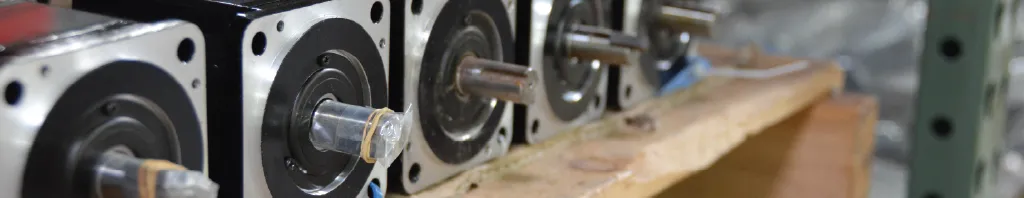

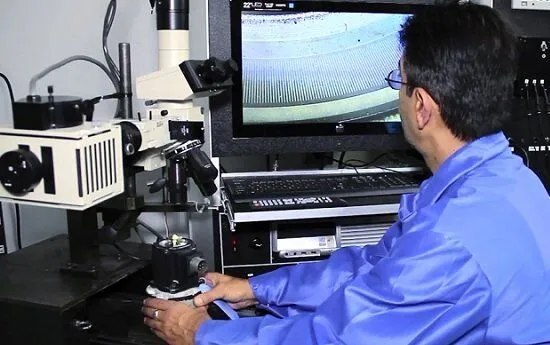

Precision Zone’s 72,000 sq foot facility is equipped to handle any industrial electronics repair. We have all the necessary tools to evaluate and repair your motor from multimeters and IR cameras, to megohm meters and oscilloscopes. Our large inventory of spare parts guarantees a quick turn-around. Precision Zone has custom built simulators to test the motor in real-life conditions once the repair is complete.

(847) 465-9060

(847) 465-9060