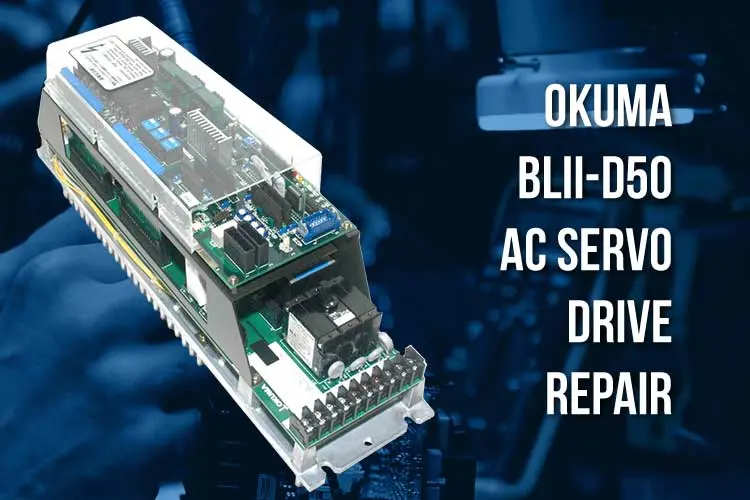

Okuma’s BLII-D servo amplifiers come in two varieties – a single axis or dual axis offering. The naming convention of the unit distinctly identifies the power rating of the axes. The single axis drives range from 15kW to 150kW whereas the dual axis version will range between 15kW per axis and can go up to 75kW per axis.

The drive is designed to be compact and efficient while allowing for easy-to-see alarm and status monitoring with the clearly visible LEDs located on the main control card. Using check pins on the main servo control board, motor speed and torque can be check as voltage outputs.

Common Failures – Alarm Code LEDs and General Troubleshooting Steps:

With this series of Okuma servo drives, there are a few alarms which tend to show up more often than the rest and will be clearly visible by the LEDs located on the control card. These tend to be OCM (overcurrent – motor), OCS (overcurrent – servo), and OV (overvoltage).

OCM and OCS are some of the most common issues and can stem from a few different locations. One of the first checks that can be done once one of these alarms occur is disconnecting the motor leads (U, V, W) from the drive and check each output phase of the drive to the ground for any short in the circuit. If this passes and there is no short between ground and each leg, it can then be attempted to run with the motor disconnected and verify if the alarm still occurs or if a different alarm comes up. In many cases, if the OCM or OCS reoccurs after disconnecting the motor leads, there is an internal fault that usually requires further evaluation and repair. When this alarm occurs, regardless of the previously mentioned test results, it is always recommended to meg the motor using a megohmmeter which checks the insulation as well as checking the resistance between each phase combination.

Additionally, overvoltage is another alarm the commonly occurs with this type of drive. Depending on when this alarm is occurring, different troubleshooting steps can be taken to determine where the fault stems from. An issue with incoming voltage can cause this if the source is too high for the drive. On top of that, if the fault occurs during deceleration of the motor it can be linked to a faulty motor or trouble in the regenerative section of the drive.

A full list of alarms for this series of drive can be found here.

(847) 465-9060

(847) 465-9060  Back

Back